R&D in electronics, software and mechatronics — under one roof.

We turn your vision into fully functional, certified hardware ready for the global market.

Bringing hardware to life is complex. We bridge the gaps preventing your success.

Limited engineering team and product design experience.

No access to laboratories and specialized equipment.

Uncertainty around regulatory requirements and certification.

Challenges in moving from prototype to mass manufacturing.

SCIENFOSS is an end-to-end R&D partner for hardware products.

We take full ownership of engineering, integration and delivery — from early design decisions to production-ready systems.

Complete design — from schematics to production-ready PCBs.

Analog, digital and power electronics, from simple IoT devices to advanced systems.

Robust and secure firmware at the core of the product.

From low-level bare-metal systems to embedded Linux, complemented by backend services and simple desktop or mobile applications.

Electromechanical systems designed for controlled motion.

Electric drives, robotics and motion systems — with mechanical design and enclosure prototyping delivered by trusted partners.

A transparent roadmap from the first consultation to the finished product on the shelf.

Product definition, feasibility study, and initial technical specification.

Design exploration and iterative creation of functional prototypes.

EMC and safety pre-compliance, environmental testing, and product certification.

Assembly line and automated testing implementation, quality control procedures, sourcing, and volume scaling.

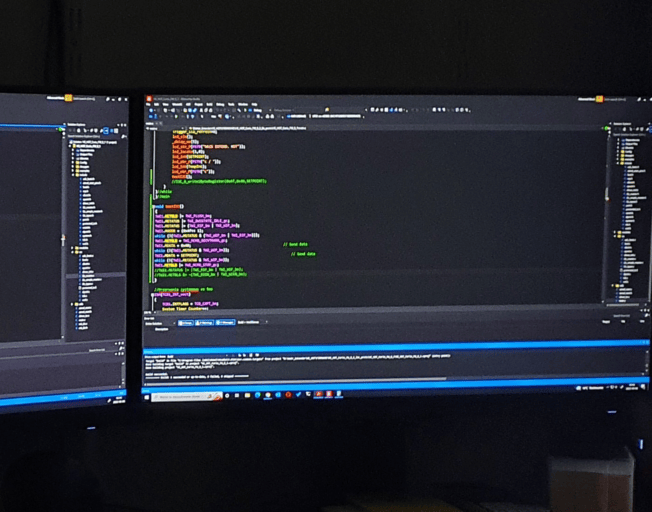

Our technical stack for modern hardware development.

SCIENFOSS operates advanced engineering labs and technical infrastructure supporting you throughout the hardware development journey.

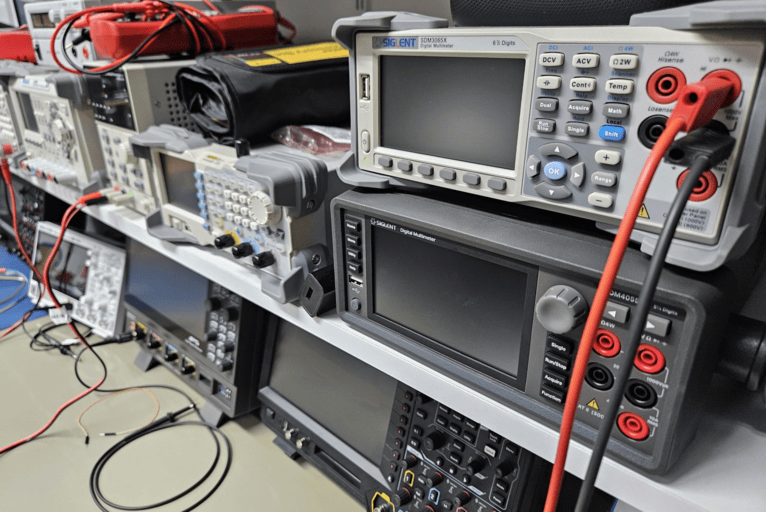

Our in-house laboratories support demanding technical work across RF systems, multi-GHz signal integrity, and power electronics from low-power designs to multi-kilowatt systems. Dedicated motor test benches for electric drives and motion control systems, as well as an RF test chamber for wireless testing, are in place.

We perform in-house EMC pre-compliance measurements and electrical safety testing to reduce certification risks early. Our labs are equipped with professional instruments, including high-bandwidth oscilloscopes, spectrum and network analyzers, and precision measurement equipment.

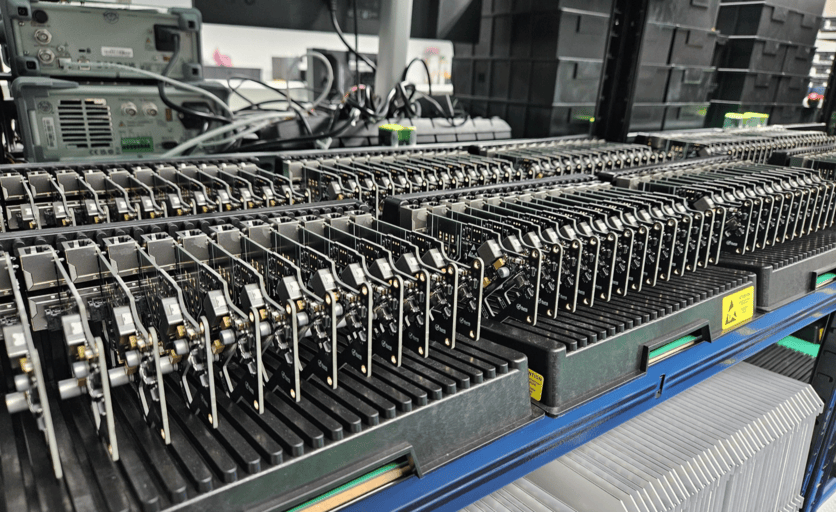

Beyond R&D, our assembly infrastructure supports both rapid prototyping and scalable manufacturing. From single prototypes to production series in the thousands per month, our processes are designed to scale as project demands grow.

Automated testing, digitally managed quality control, and a MES-based production tracking system ensure consistent product quality and traceability. This capability allows us to seamlessly transition from engineering validation to full-scale market delivery.

"This infrastructure allows us to take responsibility not only for design, but for real-world performance, compliance, and manufacturability."

DFM, DFA, DFR, and DFT principles are embedded into our engineering process to ensure that products are not only functional, but manufacturable, reliable, testable, and ready to scale.

Examples of projects we’ve worked on together with our clients.

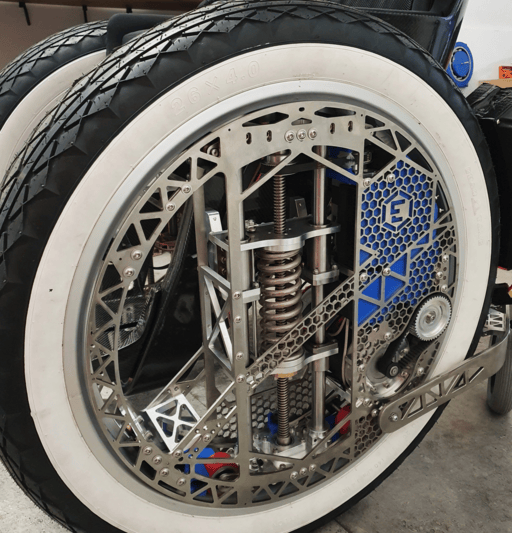

Innovative hubless drive wheel with integrated suspension, electric height adjustment, motor drive, and control electronics fully enclosed inside the wheel assembly.

More arrow_forward

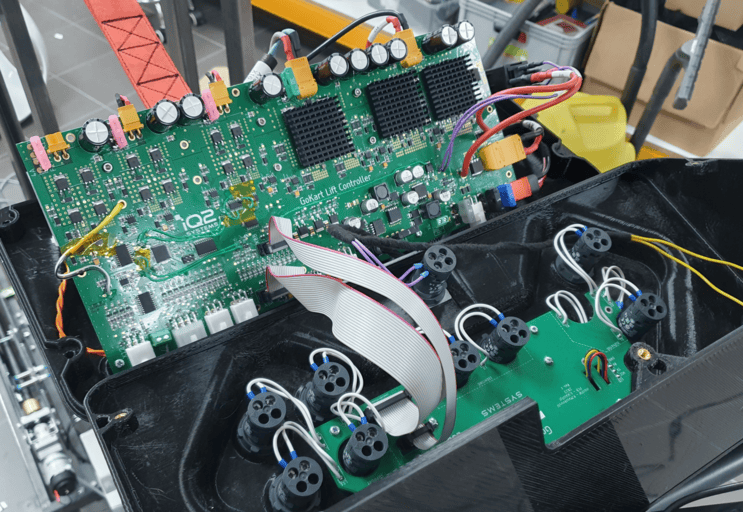

Control system for electric drives and actuators in a self-propelled platform designed for automated transport of go-karts in racing environments.

More arrow_forward

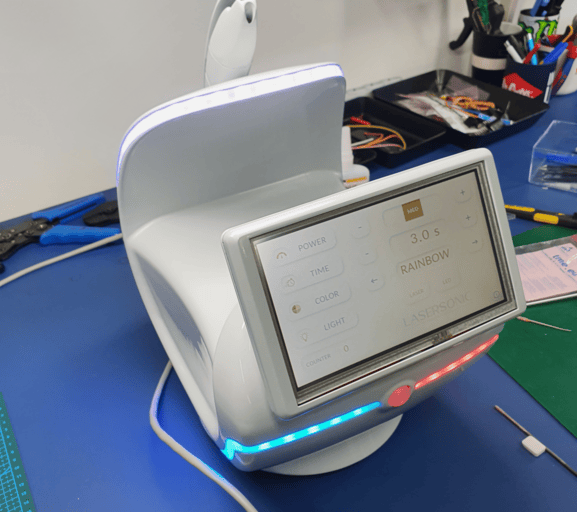

Embedded electronics and firmware for a professional ultrasonic beauty device, featuring a touch display with custom graphical user interface.

More arrow_forwardWe combine academic precision with industrial pragmatism. Our methodology ensures that your product is not only innovative but also manufacturable and cost-effective.

We are engineers at heart. We enjoy solving complex technical problems and stay deeply involved in the details until systems work reliably in real-world conditions.

A significant part of our work is done in-house, including electronics, embedded software, testing, validation, and production preparation. This allows us to move fast, iterate efficiently, and take responsibility for complete systems.

For specialized mechanical engineering, industrial design, and enclosure prototyping, we collaborate with trusted partners while retaining full system-level ownership and technical decision-making.

We have hands-on experience preparing products for compliance and certification, including CE, CB schemes, UL requirements, and medical device standards. Certification is treated as part of the engineering process, not an afterthought.

We work directly with component manufacturers and suppliers across Europe, the USA, and Asia. When required, we engage directly with factories to resolve availability, quality, and production challenges.

Talk to our engineers. We will help you assess risks, estimate costs, and choose the right technology stack.